In May 2024, I was contracted by a Canadian dealer to support the modular casework submittal package for an 11-floor hospital build. After four years of collaboration between the dealer team, GC, and client to establish approved concepts, the project had reached a pivotal stage—turning designs into detailed shop drawings. That’s where I came in, providing the technical expertise needed to bridge concepts into construction-ready documentation.

Confidential Vancouver Hospital

Starting where you are

Projects don’t always arrive neatly packaged—dealers and manufacturers often hand us drawings in various stages of completion. In this case, the dealer shared their initial layouts, which were then marked up with extensive revisions from the GC, architect, and client. Instead of letting those comments stall progress, we stepped in to digest, clarify, and streamline the feedback into polished shop drawings—submission-ready and designed to keep the project moving forward.

Getting Organized

Rather than jumping straight into shop drawings, I first developed a visual scoping map to illustrate the installation sequence. This tool not only aligned the team on process and expectations, but also enabled accurate base material calculations—delivering cost savings and greater project efficiency.

Tackling Challenges

Throughout the project, we partnered closely with the manufacturer’s engineering team to resolve technical challenges related to space and equipment integration.

In one instance, the end user requested that a piece of medical equipment be housed within the cabinetry. To make this possible, we gathered detailed cut sheet information from the GC and collaborated directly with the manufacturer’s casework engineer—ensuring a seamless fit and functionality tailored to the client’s needs.

Delivering with Precision

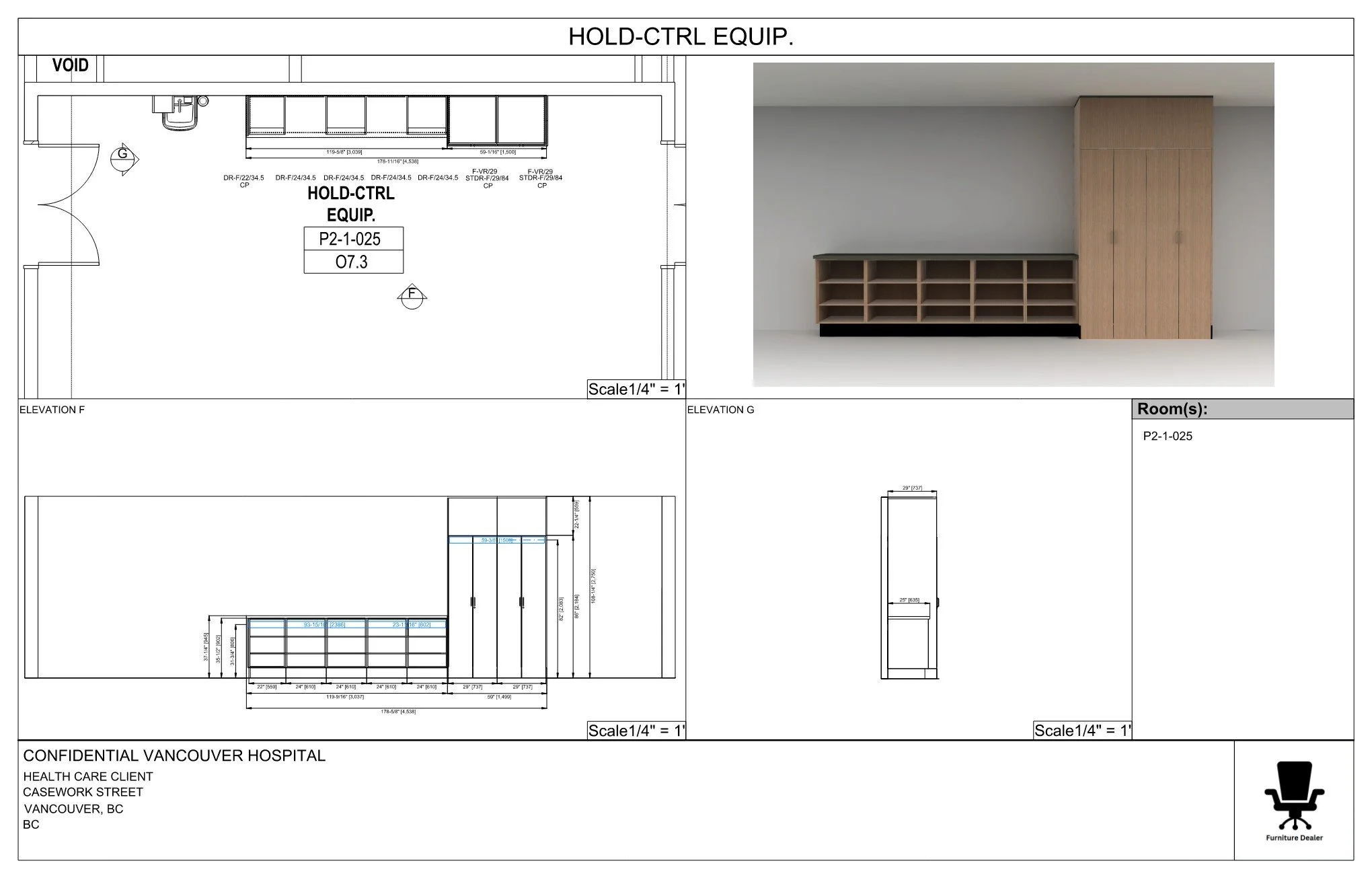

All owner and GC feedback, combined with close collaboration with the manufacturer, was integrated to produce precise, construction-ready shop drawings. These comprehensive drawings include overall floorplans, front and side elevations, and high-quality renderings for each room. Additional pages—such as color-coded floorplans, general notes, finish selections, and product specifications—ensure every submission is complete, clear, and ready for GC approval.